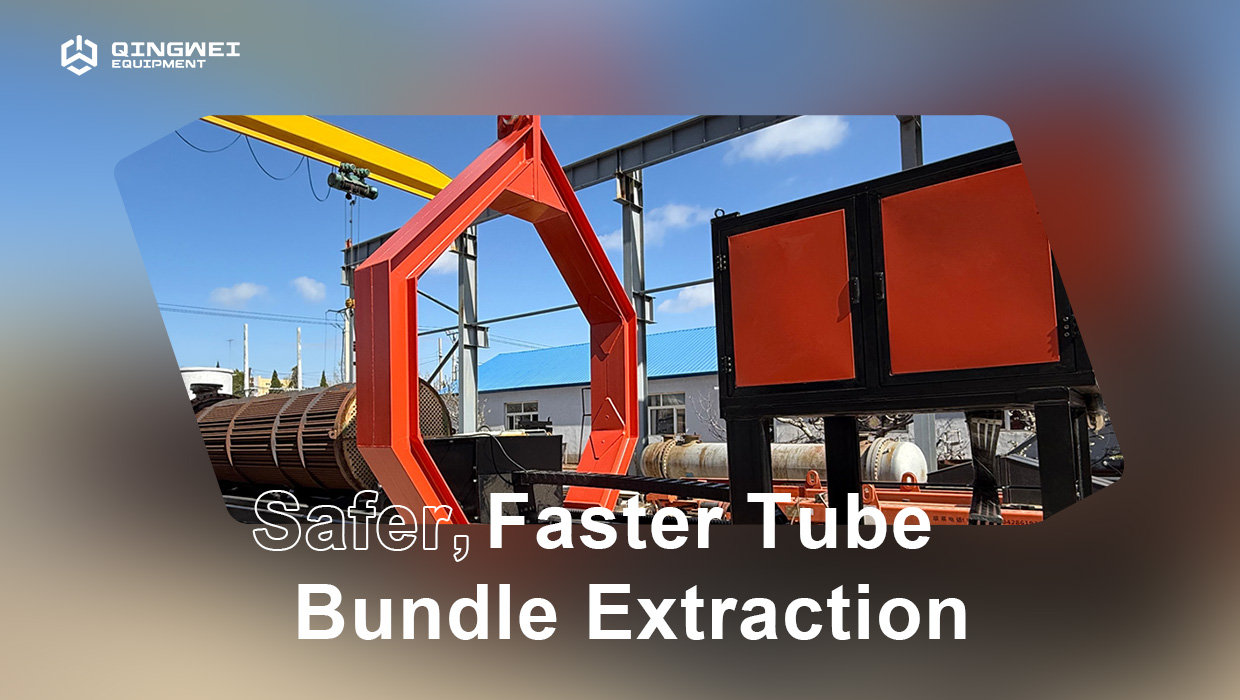

Diesel Bundle Extractor

Diesel bundle extractor is a heavy-duty hydraulic system for fast and safe removal of shell-and-tube heat exchanger bundles during plant shutdowns. With pulling capacity from 25 to 100 ton and bundle length up to 12–15 m, it is ideal for refineries, petrochemical plants and power stations.

Special Features

-

High pulling force range from 25–100 ton, suitable for heavy and fouled bundles.

-

Safe and flexible operation with hydraulic clamping and remote control.

-

Robust steel structure and proven design, already used in refineries and power plants.

15–100

Pulling force range (t)

15–100

Tube bundle load capacity (t)

6-15

Tube bundle length range (m)

100-350

Tube bundle diameter range (mm)

Diesel Bundle Extractor Models and Technical Data

Customized designs are available. Maximum bundle length up to 15 m and higher pulling force can be provided on request.

| ITEM / MODEL | QW25-6 | QW35-8 | QW45-9 | QW65-12 | QW85-12 | QW105-12 |

|---|---|---|---|---|---|---|

| Max. pulling force (T) | 25 | 35 | 45 | 65 | 85 | 105 |

| Max. load (T) | 25 | 35 | 45 | 65 | 85 | 105 |

| Max. bundle diameter (mm) | 1400 | 1600 | 2000 | 2400 | 2600 | 3000 |

| Max. bundle length (mm) | 6000 | 8000 | 9000 | 12000 | 12000 | 12000 |

| Engine | CUMMINS: QSF2.8 t3TC71 | CUMMINS: QSF2.8 t3TC71 | CUMMINS: QSF2.8 t3TC71 | CUMMINS: QSF2.8 t3TC71 | CUMMINS: QSF2.8 t3TC71 | CUMMINS: QSF2.8 t3TC71 |

| Number of cylinders | 4 | 4 | 4 | 4 | 4 | 4 |

| RPM | 2,200 | 2,200 | 2,200 | 2,200 | 2,200 | 2,200 |

| Power | 53kW | 53kW | 53kW | 53kW | 53kW | 53kW |

Pulling force test & verification

To ensure the safety and reliability of our bundle extractor, we carried out full-load pulling force tests on site.

The main test conditions were as follows:

Test machine: Diesel bundle extractor 65 T (QW65 series)

Test load: up to 70 T simulated bundle weight

Continuous pulling test duration: 30 minutes

Result: no structural deformation, normal hydraulic temperature, stable pressure without leakage.

The test proves that the actual pulling capacity meets and exceeds the rated value, providing a safe margin for field operation.

Explore our solutions

Refinery shutdown & tube bundle extraction

Diesel bundle extractors remove fouled heat exchanger bundles quickly during refinery turnarounds, cutting crane time and overall downtime.

Condenser & heat exchanger maintenance

Electric bundle extractors pull and reinsert condenser bundles safely in confined areas, ideal for power plant maintenance outages.

Emergency bundle extraction service

When a critical exchanger fails, mobile bundle extractors allow contractors to respond fast on site and restore production sooner.

Offshore platform tube bundle work

Compact bundle extractors handle exchanger bundles on offshore platforms where space is limited and lifting operations are critical.

Power plant condenser bundle extraction

High-capacity bundle extractors remove long and heavy condenser bundles in thermal and combined-cycle power plants.

Chemical plant heat exchanger service

Bundle extractors support regular cleaning and retubing work in chemical plants, improving safety compared with manual pulling.

Diesel Bundle Extractor FAQ

A: This equipment is mainly used for extracting and reinstalling tube bundles of shell-and-tube heat exchangers. It is suitable for major overhauls, shutdown maintenance, and emergency repair operations in refineries, chemical plants, LNG plants, and power plants. It is particularly well suited for projects with heavy tube bundles, severe fouling, limited on-site space, and strict requirements on minimizing downtime.

A: Model selection mainly depends on three parameters:

Maximum tube bundle weight (including fouling) – we recommend keeping a 20–30% safety margin.

Tube bundle length – standard handling range is approx. 6–15 m; beyond this can be customized.

Site conditions – for example, whether there is heavy fouling and whether frequent continuous operation is required.

For instance, if the maximum tube bundle weight is 45 t, we recommend selecting the 65T model to ensure sufficient pulling force to deal with fouling and potential sticking.

A: For standard models, the rated pulling capacity is approximately 25–100 tons. The typical tube bundle parameters it can handle are:

Tube bundle length: approx. 6–15 m

Tube bundle diameter: approx. 100–350 mm

The exact applicability should be checked against the actual heat exchanger drawings, and we can verify the parameters and recommend a suitable model based on your project data.

A:

A relatively flat and solid ground is required for placing the main unit and installing the rails.

The ground must have sufficient load-bearing capacity for the equipment weight and the tube bundle weight.

Reserve enough operating space in the length direction of the equipment so that the tube bundle can be fully extracted.

Confirm in advance the lifting conditions (crane capacity, lifting points, etc.).

If the site conditions are limited, we can provide simplified layout recommendations or customized solutions.

A: For standard models without special customization, the typical delivery time is about 3–6 months after order confirmation.

If you require special pulling capacity, extended rails, explosion-proof configuration, or other customized options, the delivery time may be slightly longer. The exact schedule will be confirmed in our official quotation and contract.