In the world of petrochemical, refinery, and power plant operations, maintenance downtime is not just costly—it’s a risk to safety and efficiency. One of the most critical tools used in heat exchanger servicing is the bundle extractor, also known as a tube bundle puller. These machines have revolutionized the way companies handle tube bundle removal and insertion, ensuring faster operations, enhanced safety, and reduced labor intensity.

At Qingwei Equipment, we specialize in the design and manufacturing of high-performance bundle extractors for the global market. Whether you operate in the Middle East, South America, Southeast Asia, or Central Asia, our machines are built to withstand harsh conditions and deliver reliable performance in every extraction cycle.

What is a Bundle Extractor?

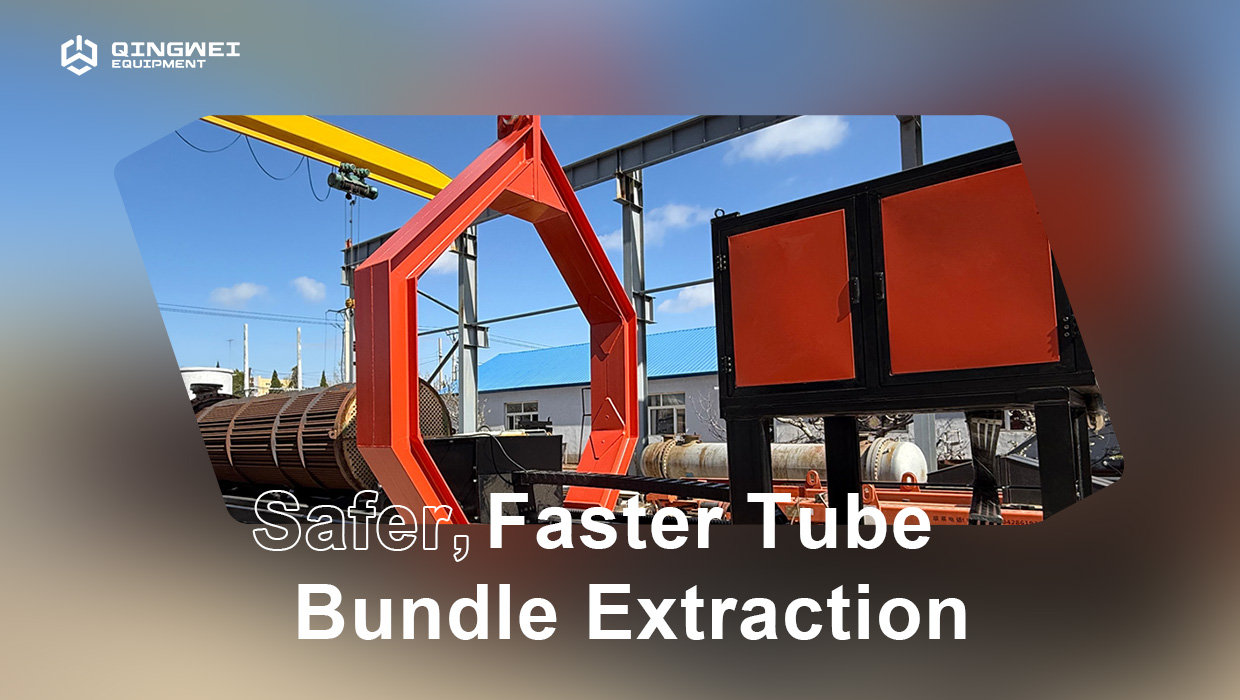

A bundle extractor is a mechanical device used to pull tube bundles out of heat exchanger shells for maintenance, cleaning, or replacement. Traditional methods often relied on cranes or manual labor, which posed safety risks and were inefficient.

Our bundle extractors are engineered to be self-propelled, remote-controlled, and capable of handling loads ranging from 15 tons to 45 tons. With stroke lengths of up to 6 meters and compatibility with bundle diameters from 300 mm to 1500 mm, they are perfect for handling a wide range of exchanger sizes.

Key Features of Qingwei Bundle Extractors

High Pulling Force: Suitable for heavy-duty heat exchanger maintenance operations.

Remote Operation: Enhances safety by allowing operators to control the unit from a safe distance.

Air- and Diesel-Powered Options: Flexible to accommodate plant energy availability.

Robust Chassis: Engineered to work reliably in offshore, desert, or confined-space environments.

Customizable Design: Available in multiple configurations depending on site requirements and heat exchanger dimensions.

Applications Across Industries

Bundle extractors are indispensable in:

Petrochemical refineries

Oil and gas plants

Chemical processing units

Power generation stations

Maintenance service contractors

They are especially critical during turnaround or shutdown periods when time and precision are key.

Why Choose Qingwei Equipment?

With over 30 years of experience in industrial equipment manufacturing, Qingwei Equipment delivers products that are tested, proven, and globally trusted. Our bundle extractors are manufactured using ISO-certified processes, and we offer international CE certification upon request.

We also offer:

Fast delivery timelines for urgent maintenance schedules.

Dedicated after-sales support, including remote diagnostics and video instructions.

Competitive pricing without compromising on build quality or performance.

Client Success Stories

Over the past year, we have delivered bundle extractors to clients in Saudi Arabia, Brazil, Kazakhstan, and Indonesia. Each client reported reduced maintenance times and improved worker safety, proving the real-world value of our solutions.

Request a Quote or Demo

Interested in upgrading your heat exchanger maintenance process? Contact us today to get a custom quote or schedule a virtual demo. We also offer exclusive pricing for bulk or distributor orders.