In the world of industrial maintenance, especially when dealing with heat exchangers, efficiency and safety are paramount. One piece of equipment that plays a crucial role in achieving both is the bundle extractor. If you're involved in power plants, refineries, chemical plants, or any industry relying on large-scale heat exchange, understanding bundle extractors is key to streamlining your operations and reducing downtime.

What Exactly Does a Bundle Extractor Do?

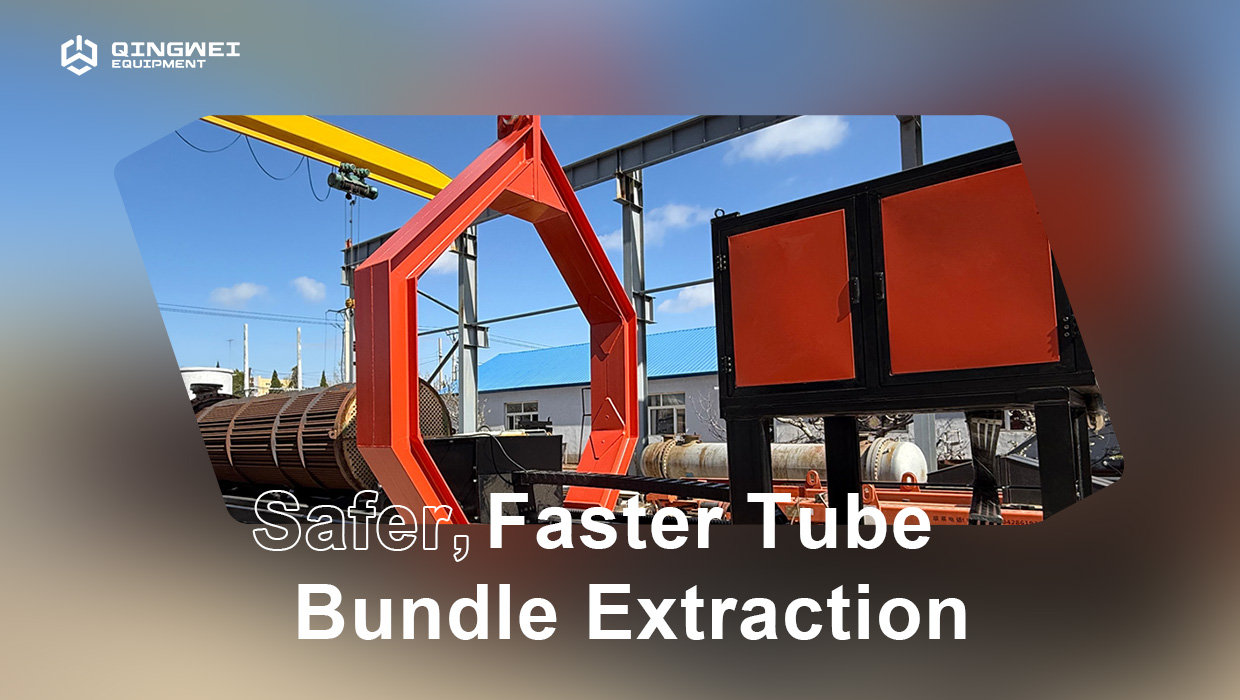

A bundle extractor is a specialized machine designed to safely and efficiently remove and insert tube bundles from heat exchanger shells. Tube bundles are the core components of a heat exchanger, consisting of a large number of tubes through which fluids flow to transfer heat. Over time, these bundles can foul, corrode, or become damaged, requiring removal for cleaning, repair, or replacement.

Manually extracting these heavy and often unwieldy bundles is not only incredibly labor-intensive and time-consuming but also poses significant safety risks to workers. This is where the bundle extractor comes in.

Types of Bundle Extractors

Bundle extractors come in various configurations to suit different needs and operational environments:

Aerial Bundle Extractors: These are typically truck-mounted units with a long boom, allowing them to access heat exchangers at various heights. They offer excellent mobility and are ideal for sites with multiple heat exchangers in different locations.

Stationary Bundle Extractors: These are designed for use in a fixed location, often within a workshop or a dedicated maintenance area. They are robust and can handle extremely heavy bundles.

Trailer-Mounted Bundle Extractors: Offering a balance between mobility and lifting capacity, these units are easily transported to different job sites.

Self-Propelled Bundle Extractors: These highly maneuverable units can move independently around a facility, providing flexibility for on-site bundle handling.

Key Benefits of Using a Bundle Extractor

Investing in or utilizing bundle extractor services offers numerous advantages for your business:

Enhanced Safety: Eliminates the need for hazardous manual lifting and pulling, significantly reducing the risk of injuries to personnel.

Increased Efficiency: Dramatically cuts down the time required for bundle extraction and insertion, leading to faster turnaround times for maintenance. This translates directly to reduced downtime for your critical equipment.

Cost Savings: By minimizing labor costs and shortening maintenance windows, bundle extractors contribute to significant operational savings. Faster maintenance also means your plant can return to production quicker, maximizing output.

Reduced Equipment Damage: The controlled and precise operation of a bundle extractor minimizes the risk of damage to the delicate tube bundle or the heat exchanger shell during removal and re-insertion.

Improved Maintenance Quality: With safer and more efficient removal, maintenance teams can perform thorough inspections, cleaning, and repairs, extending the lifespan of your heat exchangers.

Versatility: Many modern bundle extractors are designed to handle a wide range of bundle sizes and weights, offering flexibility for various heat exchanger types.

Who Needs a Bundle Extractor?

Bundle extractors are indispensable for any industry that heavily relies on heat exchangers and requires regular maintenance, including:

Oil & Gas Refineries: For efficient turnaround maintenance of crude distillation units, reboilers, and condensers.

Petrochemical Plants: Essential for maintaining reactors, heat exchangers, and other process equipment.

Power Generation Plants: Critical for servicing condensers and heat exchangers in thermal and nuclear power plants.

Chemical Processing Facilities: For safe and quick maintenance of various heat exchange systems.

HVAC & Refrigeration Industries (for larger units): While less common for smaller commercial units, large industrial chillers and heat recovery systems can benefit.

Choosing the Right Bundle Extractor or Service Provider

When considering a bundle extractor, whether for purchase or service, look for:

Reputation and Experience: Partner with a provider known for quality equipment and reliable service.

Safety Features: Ensure the equipment meets the highest safety standards and incorporates robust safety mechanisms.

Capacity and Range: Verify that the extractor can handle the size and weight of your specific heat exchanger bundles.

Mobility and Accessibility: Consider your plant layout and choose an extractor type that can easily access your heat exchangers.

After-Sales Support: Look for good warranty, spare parts availability, and technical support.

Optimize Your Operations with Bundle Extractor Technology

In today's competitive industrial landscape, maximizing uptime and ensuring worker safety are non-negotiable. Bundle extractors offer a powerful solution to these challenges, transforming what was once a laborious and risky task into a streamlined, efficient, and safe operation. By embracing this technology, you can significantly enhance your heat exchanger maintenance programs, leading to improved productivity and substantial cost savings.

Looking to enhance your heat exchanger maintenance efficiency? Contact us today to learn more about our range of high-quality bundle extractors and services.