BUNDLE EXCHANGER SOLUTIONS

Qingwei’s bundle extractors provide a safe and efficient solution for heat exchanger maintenance. They replace cranes, reduce manpower, and enhance HSE performance. Proven in refineries and petrochemical plants across the Middle East, LATAM, CIS, and APAC.

Challenges in Tube Bundle Extraction

Long turnaround times

Manual extraction and crane operations slow down shutdown schedules.

High safety risks

Heavy bundles, suspended loads, and cramped spaces increase pinch-point hazards and the risk of uncontrolled movement.

Tube bundle damage

Uneven pulling and improper support lead to costly repairs.

Limited space on site

Conventional cranes are difficult to deploy in congested units.

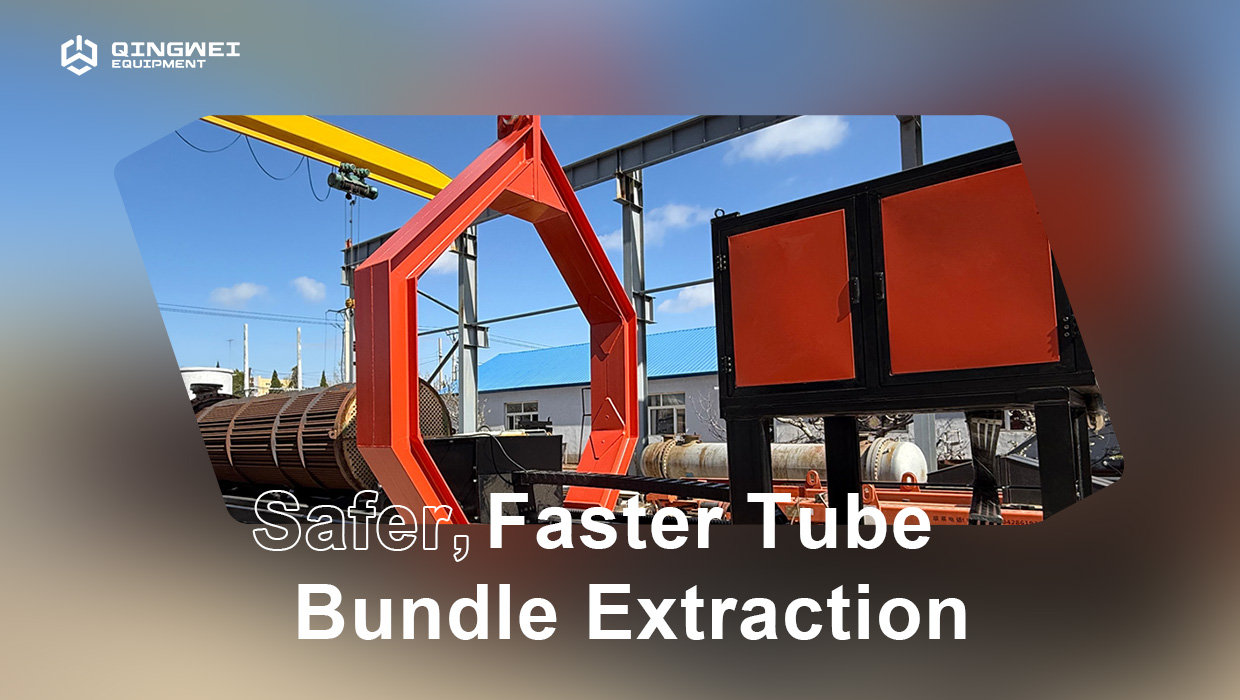

Our Solution: Tube Bundle Extraction

Our tube bundle extractor provides a complete solution for safe and efficient tube bundle removal and insertion during shutdowns. It is designed to replace risky manual pulling and heavy crane operations with controlled hydraulic force.

Position & Clamp

The extractor is aligned with the heat exchanger and securely clamped to the channel.

Hydraulic Pulling

Controlled hydraulic force smoothly pulls out the tube bundle while operators stay clear of the danger zone.

Transport & Cleaning

The bundle is placed on a trolley or rollers and moved to the cleaning or inspection area.

Reinsertion

After cleaning, the same equipment is used to push the tube bundle back into the shell quickly and safely.

Ready to see which tube bundle extractor is right for your plant and exchangers?

Product Options: Electric & Diesel-Powered Extractors

Electric Bundle Extractors

- Ideal for plants with stable power supply and strict emission regulations

- Lower noise and zero on-site exhaust emissions

- Suitable for indoor areas or enclosed units

Diesel Bundle Extractors

- Self-contained power pack – no external electricity needed

- Perfect for remote areas and outdoor shutdowns

- High mobility for large sites and multiple units

Tube Bundle Extraction by the Numbers

Our tube bundle extractors have been proven in refineries and petrochemical plants around the world.

Here are a few key numbers that show the impact on safety, efficiency and project performance.

Cut Manpower, Save Hours – Watch the Bundle Extractor Work