FOCUSED ON BUNDLE EXTRACTORS

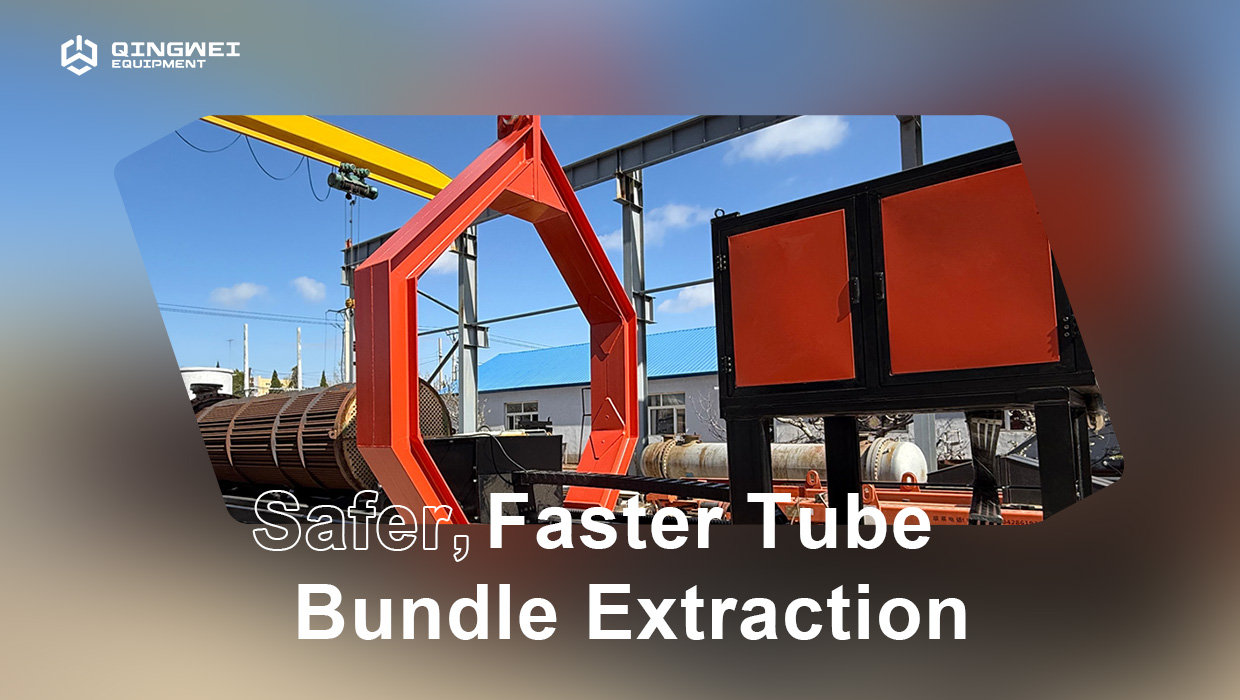

Dalian Qingwei Industrial Equipment Co., Ltd. specializes in the R&D and manufacturing of Tube Bundle Extractors / Bundle Pullers, supporting heat-exchanger maintenance for refineries, petrochemical plants, and industrial facilities. We deliver safe, reliable, and customizable extraction solutions to reduce downtime and operational risk.

Core Products and Services

Tube Bundle Extractors Only: Qingwei focuses exclusively on designing and manufacturing tube bundle extractors for refinery and petrochemical heat exchanger maintenance, allowing us to go deeper in engineering and reliability than general hydraulic tool suppliers.

In-House Engineering & Production: From structural design and hydraulic systems to welding, machining, and final assembly, every tube bundle extractor is built in our own factory under strict process control and quality inspection.

Customized to Your Exchangers: Our engineering team can tailor lifting capacity, stroke, frame dimensions, rail layout, and control options to match your heat exchanger configuration, plant layout, and turnaround schedule.

Safety and Efficiency Focused: Each machine is engineered for safe tube bundle extraction and installation, reducing manual handling, minimizing unplanned downtime, and helping plants complete turnarounds faster and more reliably.

Lifecycle Service Support: We provide on-site commissioning, operator training, technical troubleshooting, spare parts, and overhaul services to keep your tube bundle extractor performing throughout its service life.

One-stop manufacturing service

Comprehensive manufacturing capabilities

Technological Leadership: Continuous investment in R&D ensures our products comply with international standards such as ISO and CE, adapting to various working conditions worldwide.

Quality Assurance: From raw material procurement to final product delivery, we implement strict quality control measures to guarantee durability and operational safety.

Global Service Network: A dedicated rapid-response team provides multilingual technical support, customized solutions, and efficient logistics services, covering markets in Asia, Europe, the Middle East, and South America.

Customer-Centric Approach: We tailor product specifications to meet customer needs and offer one-stop pre-sales consultation and after-sales maintenance support.

Production Workshop

Production Workshop

Production Workshop

Production Workshop

Why Choose Qingwei?

Factory Advantages

Factory

Our factory operates with a substantial and verifiable scale, boasting modern production facilities, advanced equipment, and a trained workforce.

Quality

We will manufacture products that match or exceed the best available globally, while also delivering additional value to our customers.

On-Time Delivery

Timely dispatch guaranteed via optimized supply chains, with flexible production schedules to accommodate urgent orders.

Price

Competitive pricing without compromising quality, achieved through efficient manufacturing and bulk material sourcing.

After-Sales

Prompt support via multilingual teams, offering repairs, replacements, and proactive issue resolution.

Technology

Cutting-edge machinery and R&D expertise enable precision engineering and tailored solutions for diverse markets.

FAQ

Qingwei is a vertically integrated manufacturer specializing in R&D and production of industrial maintenance solutions, covering hydraulic wrenches, high-pressure pumps, bundle extractors, and bundle cleaner. Equipped with core technologies like high-precision torque control and AI-driven cleaning, our ISO 9001-certified facilities feature CNC machining centers and advanced testing labs. We offer customized solutions and meet ASME/API standards. Serving clients in over 30 countries, we build long-term partnerships through technical support and predictive maintenance, empowering global industries with innovative, sustainable technologies.

Qingwei Industries operates its own ISO 9001-certified manufacturing facilities, housing advanced CNC machining centers and testing labs to ensure full vertical integration. Our in-house production capabilities enable precise control over quality, cost efficiency, and customization for hydraulic wrenches, high-pressure pumps, and tube bundle maintenance equipment. With dedicated R&D teams and strict compliance to ASME/API standards, we deliver innovative solutions directly from factory to global clients in energy, petrochemical, and marine sectors. Backed by 20+ years of expertise, our owned production lines guarantee reliable lead times, technical support, and sustainable performance for critical industrial applications.

A: For standard models, the rated pulling capacity is approximately 25–100 tons. The typical tube bundle parameters it can handle are:

Tube bundle length: approx. 6–15 m

Tube bundle diameter: approx. 100–350 mm

The exact applicability should be checked against the actual heat exchanger drawings, and we can verify the parameters and recommend a suitable model based on your project data.

A:

A relatively flat and solid ground is required for placing the main unit and installing the rails.

The ground must have sufficient load-bearing capacity for the equipment weight and the tube bundle weight.

Reserve enough operating space in the length direction of the equipment so that the tube bundle can be fully extracted.

Confirm in advance the lifting conditions (crane capacity, lifting points, etc.).

If the site conditions are limited, we can provide simplified layout recommendations or customized solutions.

A: For standard models without special customization, the typical delivery time is about 3–6 months after order confirmation.

If you require special pulling capacity, extended rails, explosion-proof configuration, or other customized options, the delivery time may be slightly longer. The exact schedule will be confirmed in our official quotation and contract.